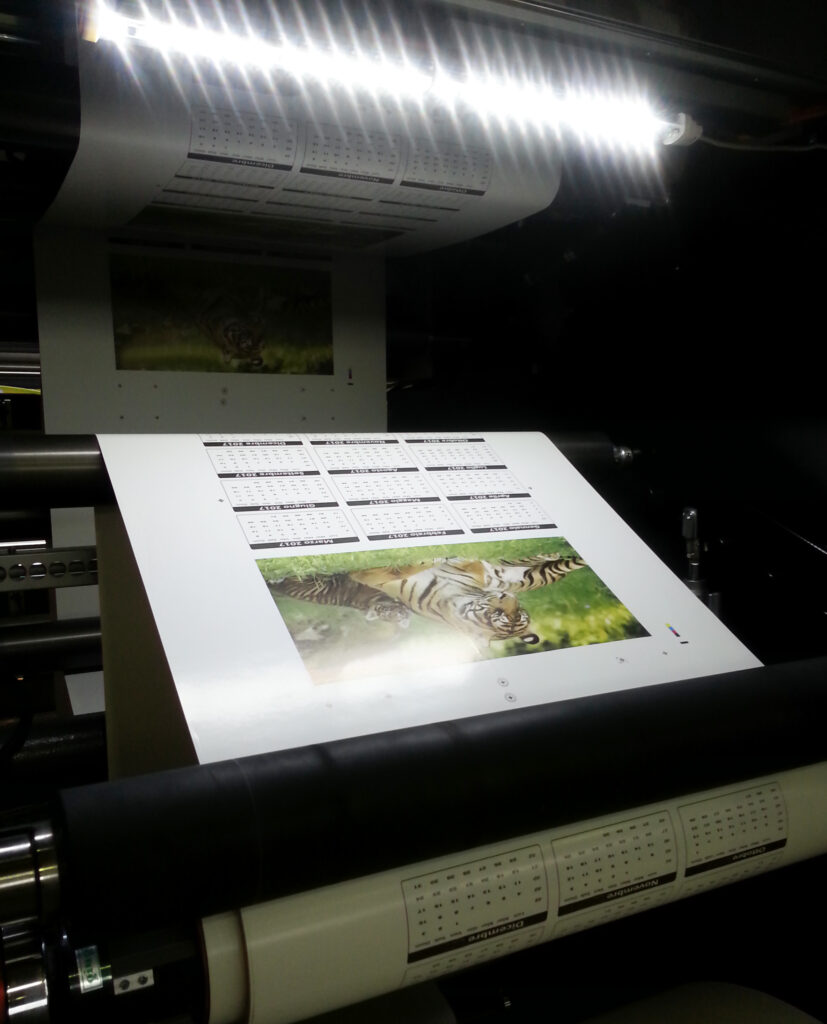

Flexographic printing, often operating behind the scenes, has a rich history filled with innovation and surprising applications that have quietly shaped our daily lives.

The historical impact of flexography

One of the earliest, and perhaps most charming, stories involve wallpaper. Before flexo became synonymous with packaging, it played a significant role in bringing affordable, patterned wallpaper to the masses. Imagine the Victorian-era homes bursting with vibrant, flexo-printed designs, a far cry from the meticulously hand-painted (and expensive) alternatives. This democratization of interior design is a testament to flexographic printing’s early impact.

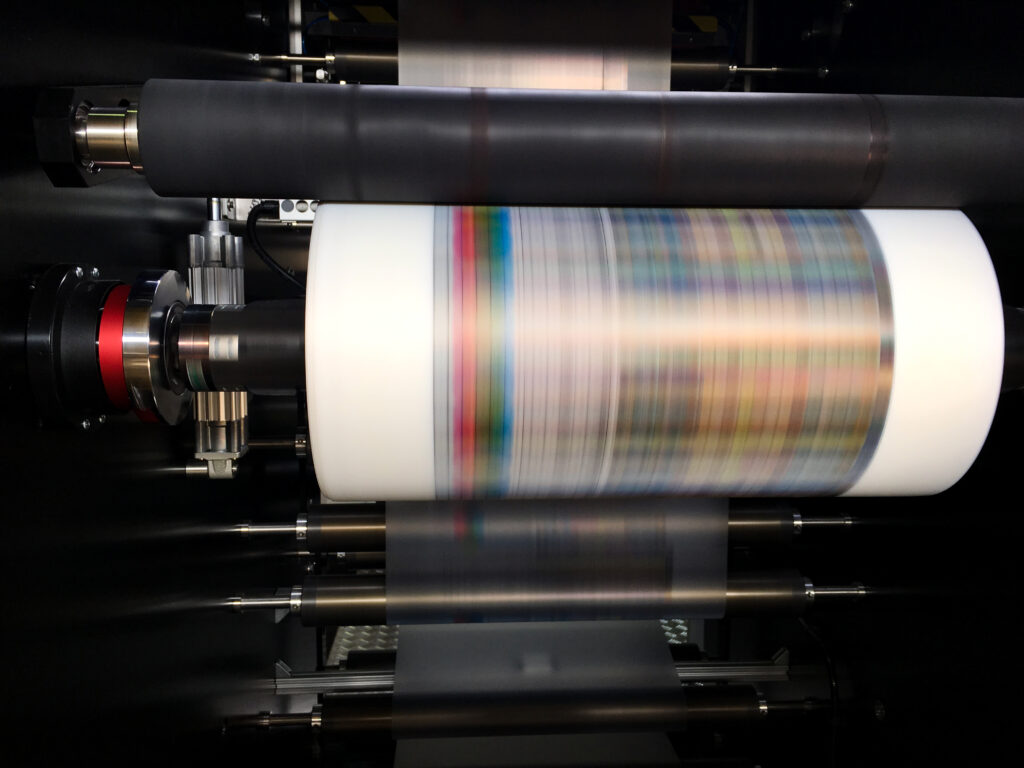

Moving into the 20th century, the rise of self-service supermarkets fueled flexo printing’s growth. Suddenly, packaging needed to be eye-catching and informative, grabbing attention on crowded shelves. The iconic branding of many household names, from breakfast cereals to cleaning products, was (and still is) brought to life through flexographic printing. Think of the bold colors and crisp graphics,that’s flexo at work.

Did you know that flexographic printing played a crucial role in the rise of the self-adhesive label industry? In the mid-20th century, as consumer goods flooded the market, the demand for efficient and versatile labeling skyrocketed. Flexo printing’s ability to print on a wide range of substrates, including thin and flexible materials, made it the ideal choice for producing vibrant, high-speed labels. This advancement not only streamlined packaging processes but also revolutionized product branding, influencing everything from soda bottles to shampoo containers.

Food sector

Flexo machine technology even found its way into the world of culinary arts. Specialty food producers began using edible inks and flexographic printing techniques to print intricate designs directly onto foods like tortillas and pastries. This not only enhanced aesthetic appeal but also opened up new avenues for branding and personalization in the food industry. Imagine biting into a cookie adorned with a custom message or a festive design, all made possible by the adaptability of flexo printing.

Sustainability

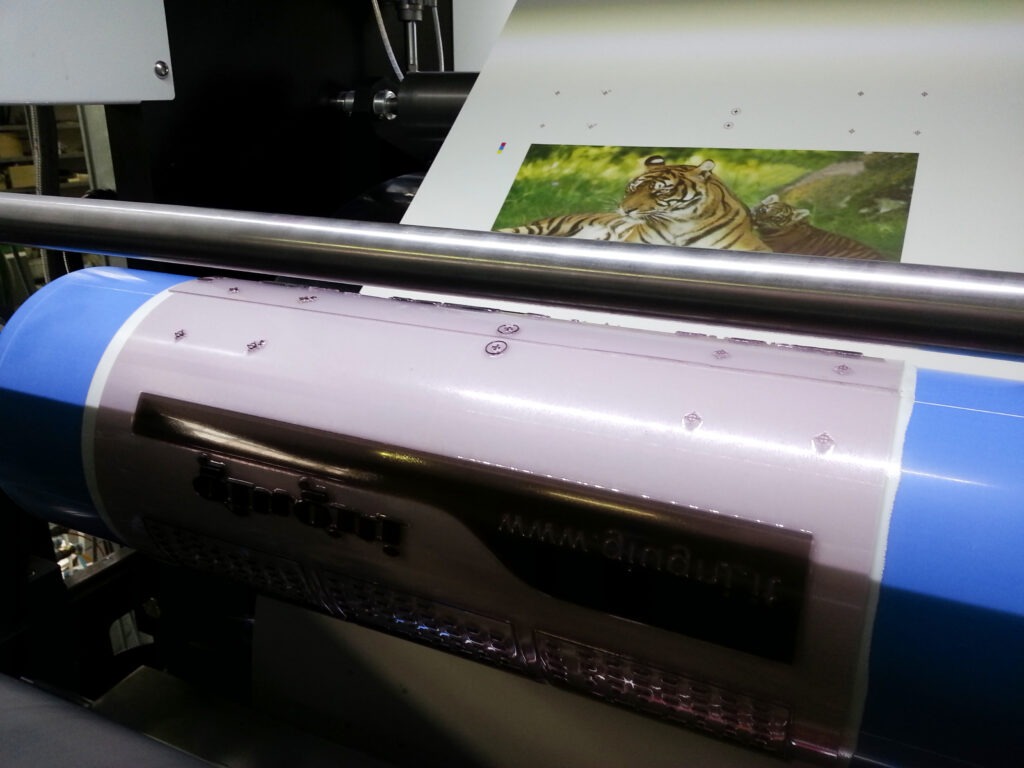

In the realm of environmental innovation, flexographic printing has been at the forefront of sustainability efforts. The development of water-based and UV-curable inks compatible with flexo printing machines has reduced reliance on solvent-based inks, minimizing volatile organic compound (VOC) emissions. Packaging companies seeking eco-friendly solutions have embraced flexo printing to meet both their environmental goals and high-quality printing needs. It’s a win-win that highlights the industry’s commitment to a greener future.

Perhaps most unexpectedly, flexographic printing has dipped into the field of electronics. Researchers are experimenting with printing flexible electronic circuits using conductive inks and flexographic machines. This method offers a cost-effective way to produce items like wearable technology and smart packaging that can interact with consumers in new and exciting ways. It’s a glimpse into how traditional flexo machines and techniques can intersect with cutting-edge technology to create something truly novel.

These stories showcase how flexographic printing, though often unnoticed, has been instrumental in driving innovation across various sectors. Its versatility and efficiency have made it a cornerstone in not just packaging but also in advancing accessibility, sustainability, and technology. As flexo printing continues to evolve, it remains an essential process for industries worldwide, proving that the work of a flexoprinter is more than just ink on a substrate, it’s a bridge between tradition and the future of printing machines.